ME100 Basics of Mechanical Engineering Module 4 :'Gears and Gear Drives'

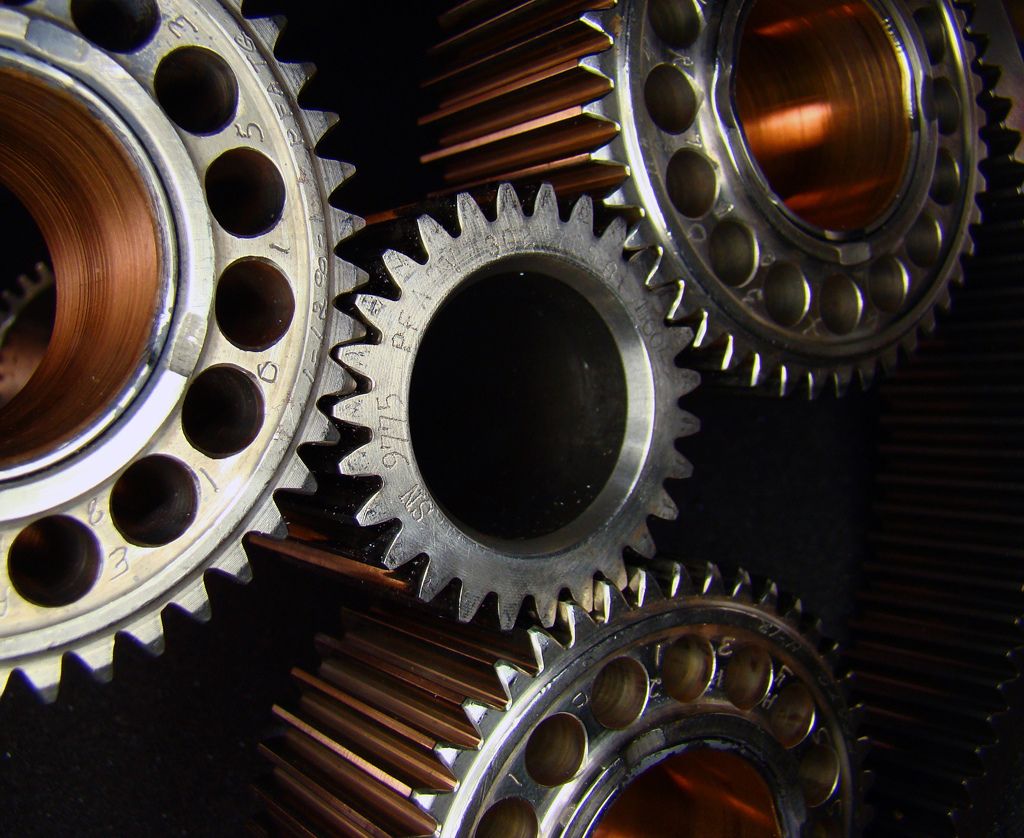

- — A gear is a toothed member.

- It is designed to transmit motion and thus power to another toothed member by successively engaging its teeth with those of the other gear

- The teeth may be cut on cylindrical or conical or rectangular or elliptical blocks.

- The tooth shape and sizes of gears are standardized.

- The gears may be manufactured from metallic or nonmetallic materials.

- The metallic gears with cut teeth are commercially obtainable in cast iron, steel and bronze.

The main types of gears are as follows

- — Spur Gear

- — Helical gear

- — Herringbone gears

- — Bevel Gears

- Worm Gears

- Rack and pinion Gears

- These are drives which transmit motion and thus power from one shaft to another with the help of gears when the distance between them is relatively small.

- The axes of the shafts may be parallel, non-parallel or intersecting.

- These are positive drives.

- They transmit power at a constant speed ratio

- It is a positive smooth drive

- — Operation is smooth and service is reliable.

- —Transmit comparatively more power

- Transmit power in any desired direction

- Gear wheels are interchangeable except Bevel gears

- — Not suitable for large center distance because the drive becomes bulky

- Production cost is high and efficiency is less

- — Needs lubrication, hence maintenance cost is there.

![Model Question Paper:Thermal Engineering [ME204]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiiWfMso0XIgfl1apSV-U0P4cml_X8Vfk0IkEP39mbVXHduoI7-t0d1MFRJeWM-EqmMCghc4fC31DsLJgoa7gxsLbAJK-hyOCY7rOyMzCEAl-CY8soMnuRoU6lPo1ncUAQX0mkz7zIHw6s/s72-c/ktu+Thermal+Engineering+%255BME204%255D.jpg)

![S5 Syllabus Civil Engineering [CE S5]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhgxoCAN4khsM4LX5BLA1CPFVM6wl4a_hVJNXxGXp_zdU97lWNBIdFPySRJJZL-e8SBEJVv_wJQKGVmZJ2u4dplmgEIONb-nYMAVCDTNPOH8Wj0BEJKezqa6qCUYronETizeVOM25HvYR0/s72-c/ktu+ce+s5+syllabus.jpg)

No comments: